UNIT-1

Stanson Rubber Products, Unit -1

-

Injection, transfer and compression moulding with state of machines

-

Dedicated mixing unit with state of the art laboratory

-

Expertise in all kinds of rubber for tough applications

Cutting

Preformed batch is quality checked and approved by in-house laboratory

Batch is fed in cutting machine and cut as per mould cavity are weighed and noted.

Quality verification

Part is checked and verified by the quality team

Send to FG stores and sent to customer as promised on time.

Mixing

Elastomer is sheared and broken down, this process is know as mastification

Chemicals are added as per requirement of end product

Moulding

Compression, Injection or Transfer moulding is carried out.

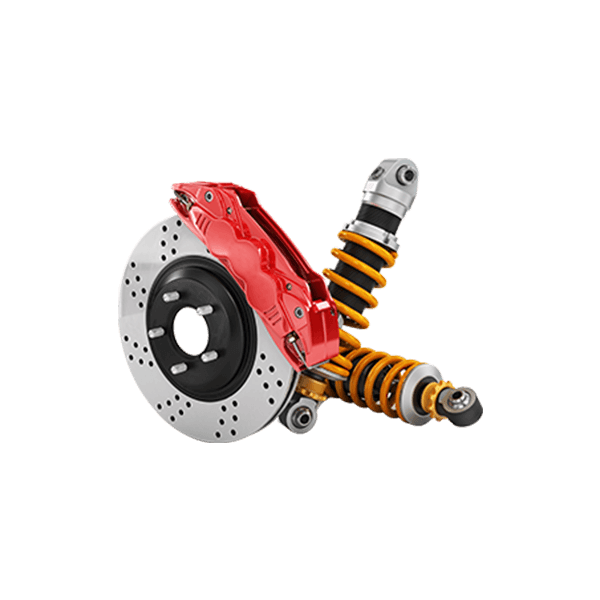

Parts Produced by SRP Unit-1

UNIT-2

Stanson Rubber Products, Unit -2

-

Extrusion of major rubber varieties of varied lengths and dimensions

-

Flexible to run solid or sponge in single line

-

Printing and assembly of hoses

Extrusion

Extrusion is carried out through continuous vulcanization line

A fully automated line with rubber only fed in one end.

Quality Checked & Wounded

Final product is checked and verified by the quality team.

Is winded and cut as per requirement

Mixing

Elastomer is sheared and broken down, this process is know as mastification

Chemicals are added as per requirement of end product

Printing

Printing is carried out as required